Panel Mount Roller Plunger Basic Switch

-

High Precision

-

Enhanced Life

-

Widely Used

Product Description

Panel Mount Roller Plunger basic switch combines the robustness of a panel mount design with the smooth operation of a roller plunger, suitable for cam actuation of switches. It is ideal for applications requiring smooth actuation and reliable performance, such as conveyor systems and automated equipment.

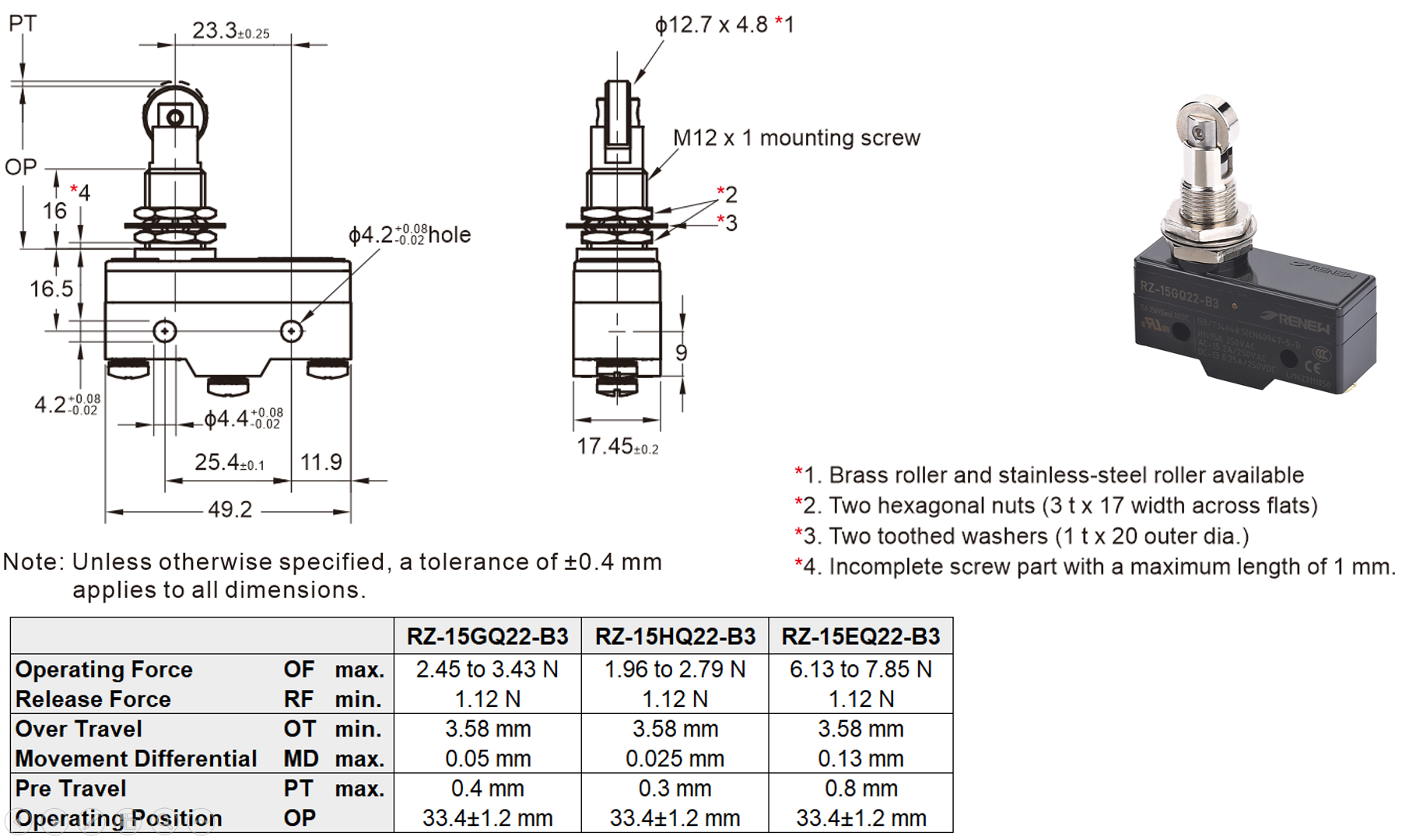

Dimensions and Operating Characteristics

General Technical Data

| Rating | 15 A, 250 VAC |

| Insulation resistance | 100 MΩ min. (at 500 VDC) |

| Contact resistance | 15 mΩ max. (initial value) |

| Dielectric strength | Between contacts of same polarity Contact gap G: 1,000 VAC, 50/60 Hz for 1 min Contact gap H: 600 VAC, 50/60 Hz for 1 min Contact gap E: 1,500 VAC, 50/60 Hz for 1 min |

| Between current-carrying metal parts and ground, and between each terminal and non-current-carrying metal parts 2,000 VAC, 50/60 Hz for 1 min | |

| Vibration resistance for malfunction | 10 to 55 Hz, 1.5 mm double amplitude (malfunction: 1 ms max.) |

| Mechanical life | Contact gap G, H: 10,000,000 operations min. Contact gap E: 300,000 operations |

| Electrical life | Contact gap G, H: 500,000 operations min. Contact gap E: 100,000 operations min. |

| Degree of protection | General-purpose: IP00 Drip-proof: equivalent to IP62 (except terminals) |

Application

Renew’s basic switches play a critical role in ensuring the safety, precision, and reliability of various devices across different fields. Here are some popular or potential application.

Industrial Machinery

Used in industrial applications such as industrial air compressors and hydraulic and pneumatic systems to limit the maximum movement for pieces of equipment, ensuring precise positioning and safe operation during processing.

Valves and Flow Meters

Employed on valves to monitor the position of the valve handle by indicating if the switch is actuated. In this case, basic switches perform position sensing on cams with no power consumption.

Articulated robotic arms and grippers

Integrated into articulated robotic arms for use in control assemblies and provide end-of-travel and grid-style guidance. Integrated into grippers of the robotic arm wrist to sense grip pressure.