Low-force Hinge Lever Basic Switch

-

High Precision

-

Enhanced Life

-

Widely Used

Product Description

By lengthening the hinge lever, the operating force (OF) of the switch can be reduced to as low as 58.8 mN, making it ideal for devices that require delicate operation. The lever design has more design flexibility as it has longer stroke length, allowing for easy activation and is perfect for applications where space constraints or awkward angles make direct actuation difficult.

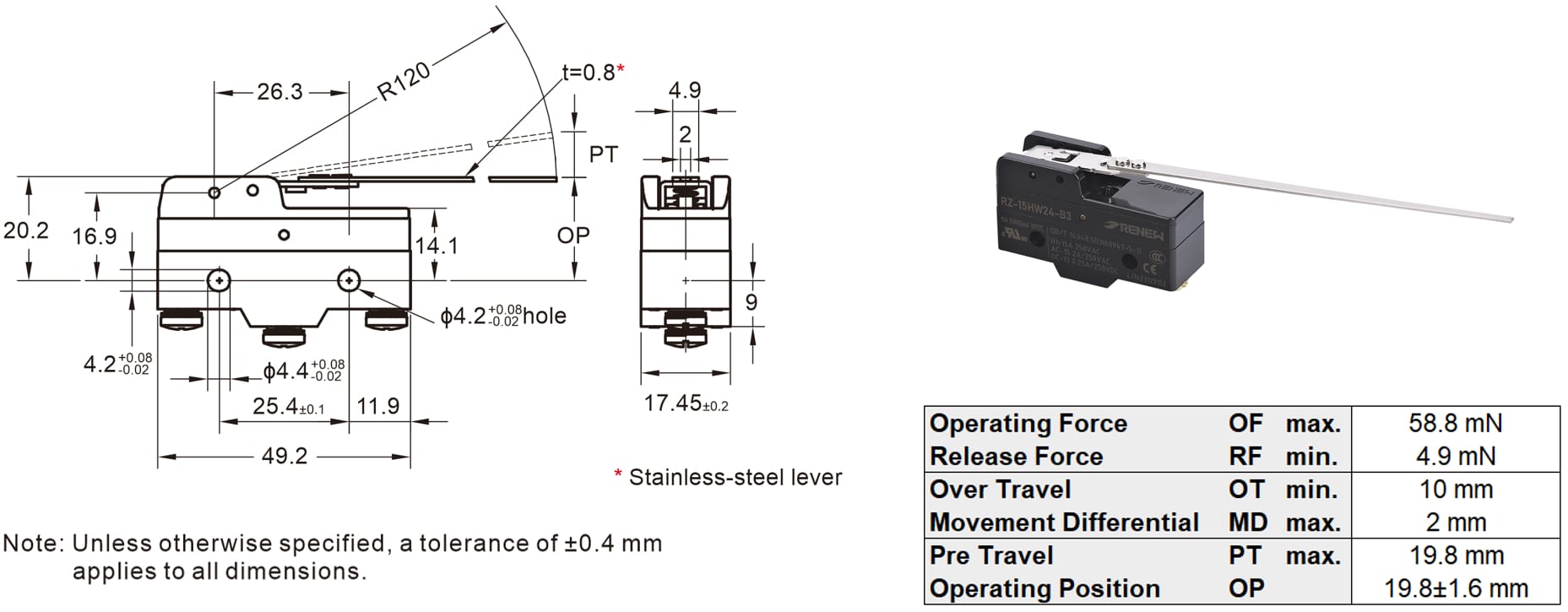

Dimensions and Operating Characteristics

General Technical Data

| Rating | 15 A, 250 VAC |

| Insulation resistance | 100 MΩ min. (at 500 VDC) |

| Contact resistance | 15 mΩ max. (initial value) |

| Dielectric strength | Between contacts of same polarity Contact gap G: 1,000 VAC, 50/60 Hz for 1 min Contact gap H: 600 VAC, 50/60 Hz for 1 min Contact gap E: 1,500 VAC, 50/60 Hz for 1 min |

| Between current-carrying metal parts and ground, and between each terminal and non-current-carrying metal parts 2,000 VAC, 50/60 Hz for 1 min | |

| Vibration resistance for malfunction | 10 to 55 Hz, 1.5 mm double amplitude (malfunction: 1 ms max.) |

| Mechanical life | Contact gap G, H: 10,000,000 operations min. Contact gap E: 300,000 operations |

| Electrical life | Contact gap G, H: 500,000 operations min. Contact gap E: 100,000 operations min. |

| Degree of protection | General-purpose: IP00 Drip-proof: equivalent to IP62 (except terminals) |

Application

Renew's basic switches play a key role in ensuring the safe, precise and reliable operation of various types of equipment in different fields. Some common or potential applications are listed below.

Sensors and monitoring devices

Sensors and monitoring devices are commonly used in industrial applications to control pressure and flow by acting as snap-acting mechanisms within equipment. These devices can monitor and adjust key parameters in industrial systems in real time to ensure stable operation and efficient production of the system. In addition, they can provide data feedback to help operators optimize and troubleshoot systems.

Industrial Machinery

In industrial machinery, these sensors and monitoring devices are widely used on machine tools. They not only limit the maximum movement of the equipment, but also accurately detect the position of the workpiece, ensuring precise positioning and safe operation during processing. The application of these equipment greatly improves production efficiency and product quality, while reducing equipment failure and operational risks.

Agricultural and gardening devices

Sensors and monitoring equipment also play an important role in agricultural and horticultural equipment. They are used for position and status detection of agricultural vehicles and garden equipment, as well as for maintenance and diagnostics. For example, a basic switch monitors the position of the lawn mower deck to ensure it is at the desired cutting height for optimal cutting results.