Hinge Lever Basic Switch

-

High Precision

-

Enhanced Life

-

Widely Used

Product Description

The switch with hinge lever actuator offers extended reach and flexibility in actuation. The lever design has more design flexibility as it has longer stroke length, allowing for easy activation and is perfect for applications where space constraints or awkward angles make direct actuation difficult. It permits actuation by a low velocity cam, and is commonly used in household appliances and industrial controls.

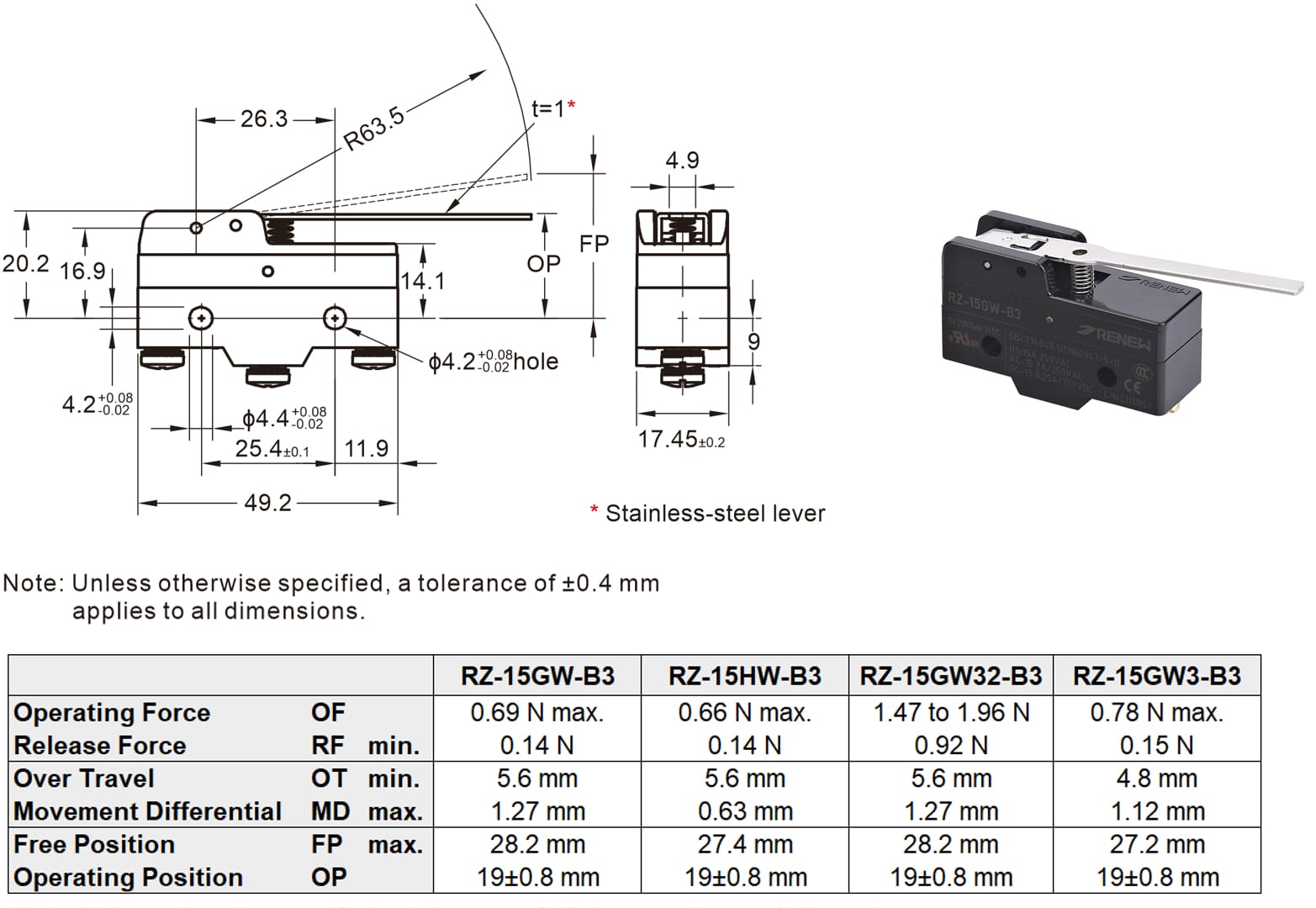

Dimensions and Operating Characteristics

General Technical Data

| Rating | 15 A, 250 VAC |

| Insulation resistance | 100 MΩ min. (at 500 VDC) |

| Contact resistance | 15 mΩ max. (initial value) |

| Dielectric strength | Between contacts of same polarity Contact gap G: 1,000 VAC, 50/60 Hz for 1 min Contact gap H: 600 VAC, 50/60 Hz for 1 min Contact gap E: 1,500 VAC, 50/60 Hz for 1 min |

| Between current-carrying metal parts and ground, and between each terminal and non-current-carrying metal parts 2,000 VAC, 50/60 Hz for 1 min | |

| Vibration resistance for malfunction | 10 to 55 Hz, 1.5 mm double amplitude (malfunction: 1 ms max.) |

| Mechanical life | Contact gap G, H: 10,000,000 operations min. Contact gap E: 300,000 operations |

| Electrical life | Contact gap G, H: 500,000 operations min. Contact gap E: 100,000 operations min. |

| Degree of protection | General-purpose: IP00 Drip-proof: equivalent to IP62 (except terminals) |

Application

Renew’s basic switches play a critical role in ensuring the safety, precision, and reliability of various devices across different fields. Here are some popular or potential application.

Sensors and monitoring devices

These devices are commonly used in sensor and monitoring systems in industrial environments and their primary function is to precisely control and regulate pressure and flow by acting as a rapid response mechanism within the device. These sensors and monitoring equipment play a key role in industrial automation, ensuring the stability and efficiency of system operations while improving the safety and reliability of the production process.

Medical instrumentation

These devices are widely used in the medical and dental fields and are often used with foot switches to achieve precise control of dental drill operations and to flexibly adjust the position of the examination chair. These medical instruments play an important role in surgery and diagnosis and treatment, ensuring that doctors can operate efficiently and safely while improving patient comfort and treatment results.

Articulated robotic arms and grippers

In articulated robot arms and grippers, sensors and switches are integrated into the robot arm to control the movement of individual components and provide end-of-stroke and grid-style guidance. These devices ensure precise positioning and safe operation of the robotic arm during operation. In addition, sensors and switches are integrated into the gripper of the robotic arm’s wrist to sense clamping pressure, ensuring precision and safety when handling items. These capabilities make articulated robotic arms play an important role in industrial automation and precision manufacturing.